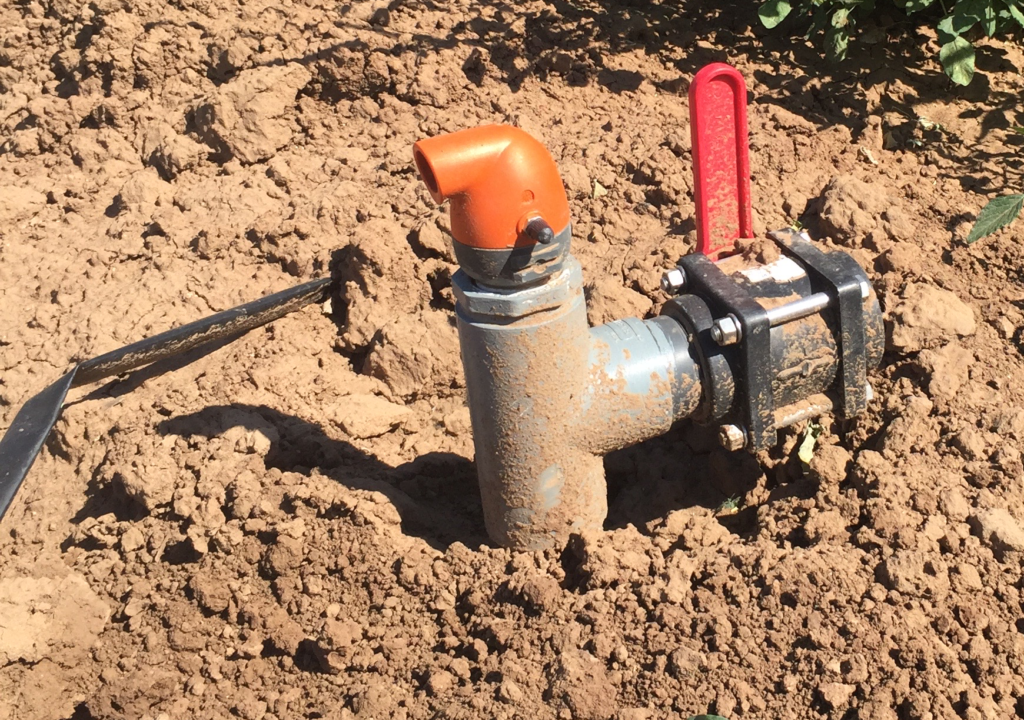

Flush Riser Assembly

Subsurface drip irrigation systems require regular maintenance in order to prevent emitter clogging and related problems. D&H engineering design requirements for regular maintenance always consists of a dripline flushing manifold or submain connected to the end of the laterals on each zone. This flushing manifold allows the laterals to be flushed with a water flow velocity higher than the normal operational flow velocity when a flushing valve attached to the manifold is opened. The higher flow velocity allows some small amount of scouring to help remove settled solids and precipitants from the system to help prevent emitter plugging. Flushing manifold pipe sizes are determined by considering the actual flow through the end of the laterals or driplines during flushing.